Part 1: Gas Analysis of O2, SO2, NOx and CO

In accordance with NEMAQA

1. Summary

The National Environmental Management: Air Quality Act of 2004 requires Listed Activities (Section 21) and Controlled Emitters (Section 23) to undergo stack emissions testing. The pollutants must be tested using the sampling methods listed in Annexure A of NEMAQA Section 21 and Section 23. Annexure A lists ISO, United States EPA and British Standards as suitable testing methods. An instrumental gas analyser is used to measure sulphur dioxide (SO2), carbon monoxide (CO) and oxides of nitrogen (NOx). NOx is comprised of NO and NO2 . Oxygen (O2 ) must also be measured and is used for normalisation to the oxygen reference which is specified by NEMAQA (there are different oxygen references for each listed activity). It is difficult to know if a gas analyser is compliant with the standards in NEMAQA because there are many different makes and models of analysers. This guide clearly describes what is required for a gas analyser to be suitable for compliance testing. This guide aims to assist industry and Air Quality Officers (AQO’s).

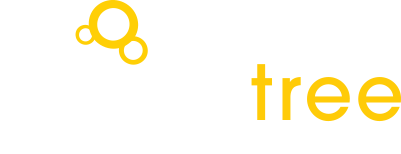

2. Compliant Gas Analysers

The most widely used gas analysers in South Africa that are fit for compliance testing are the Testo 350, the Ecom J2KN, and the Horiba (pictures beneath). Other compliant gas analysers include the Bacharach ECA 450, Enerac 700, E-Instrument 8500, Madur GA 21, and the MRU Nova Plus.

3. Non-Compliant Gas Analysers

The general guidelines are as follows.

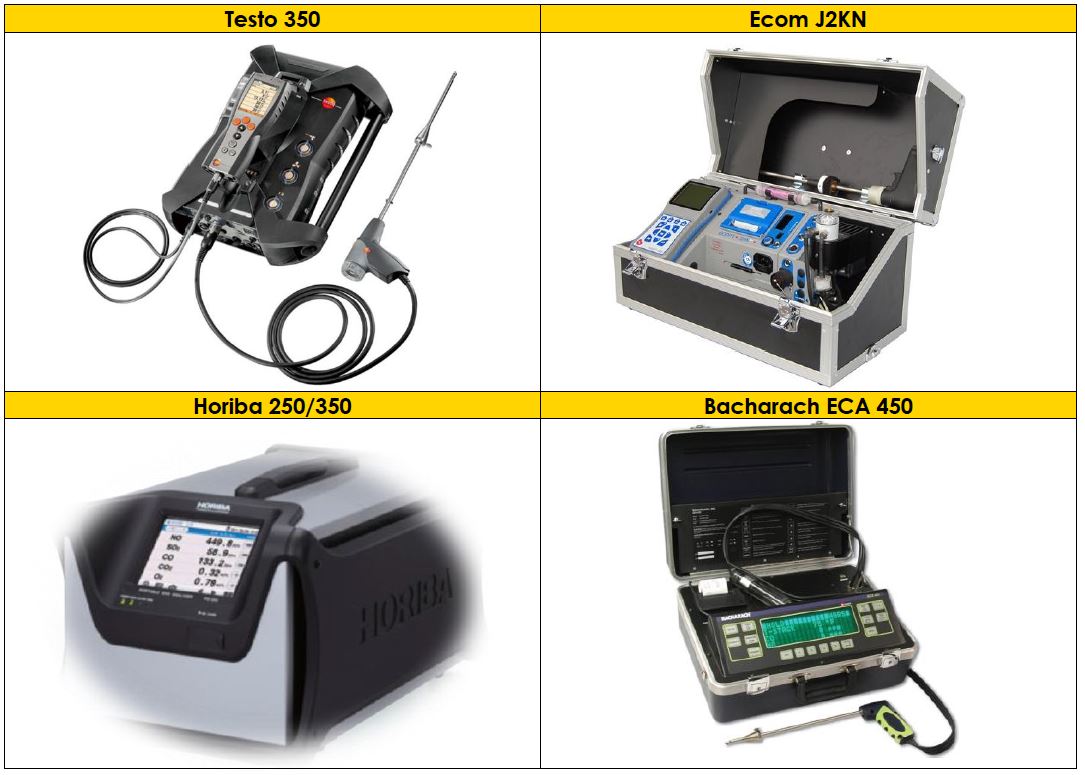

- Hand held analysers are usually not fit for compliance testing because they are too small to accommodate a Peltier cooler (thermoelectric chiller) to dry the gas. Conversely, compliance analysers usually come in large cases for this reason (see pictures above).

- Any analyser with a model number lower than those mentioned above is not fit for compliance testing. (E.g. The Testo 350 is appropriate for compliance testing. However, the Testo 310, 320, 330, and 340 are not fit for compliance measurement because they are either not equipped with an NO2 cell, a Peltier cooler / thermoelectric chiller, or a heated line).

- The analysers beneath are commonly used in South Africa by fraudulent testing companies and are not acceptable: Oldham MX 2100; Dräger MSI; Kane 900; Testo 310, 320, 330, 340; E-Instrument E1500, E4400, E5500; ECOM B; Bacharach Fyrite / PCA; IMR USA IX616, 1400PS.

- Reports where these analysers have been used should be rejected.

- Special mention must be made of the Oldham MX 2100 which a testing company in Valhalla, Centurion uses. This is the worst of all. It is not an analyser. It is a building gas detector and cannot measure in the required ranges. See a devastating story about this in Section 6.3.

Lastly, it must be noted that although some analysers can measure HCl, H2S, and NH3, it is not legal to use even a compliant analyser to measure these compounds. This is because these compounds are highly soluble in water. These compounds must be sampled isokinetically using wet chemistry or through a sulphur compound reduction (EPA16C) in the case of H2S. This will be covered in Part 2 of this series of guides.

4. What Makes a Gas Analyser Compliant?

1. It has a heated probe and a heated Teflon sampling line.

2. It has cells for measuring O2, NO, NO2, SO2 and CO. Check for an NO2 cell. Cheap, non-compliant analysers do not have an NO2 cell.

3. It has a Peltier cooler / thermoelectric chiller (not a condensate trap).

4. It is checked on certified calibration gas at the start and end of every day of testing (EPA 7e).

5. The manufacturer states that the analyser is fit for compliance work.

5. Action

1. The report should always state what analyser was used. Check the report. Most of the time the analyser will be one of those mentioned in this guide. If it is not mentioned above, perform a Google search for the brochure. Look for the following:

a. Does the brochure say it is fit for regulatory or compliance testing? If so, it is acceptable!

b. Does the brochure state that the analyser comes with:

i. A Peltier cooler or thermoelectric chiller,

ii. An NO2 cell,

iii. A heated line,

If it has all three, it is fit for compliance testing.

c. Does the brochure show that it is handheld? If so, it is probably not fit for compliance work.

d. Does the brochure advertise that it is ideal for testing diesel/petrol engines? These analysers are usually not the compliance models that are needed for testing coal, HFO and biomass combustion stacks, and process stacks, under NEMAQA.

e. Does the brochure say that it has a “condensate trap”? If it does, this means that it does not have a Peltier cooler / thermoelectric chiller. It is not fit for compliance work.

2. Reject all reports that do not use analysers that are fit for compliance testing.

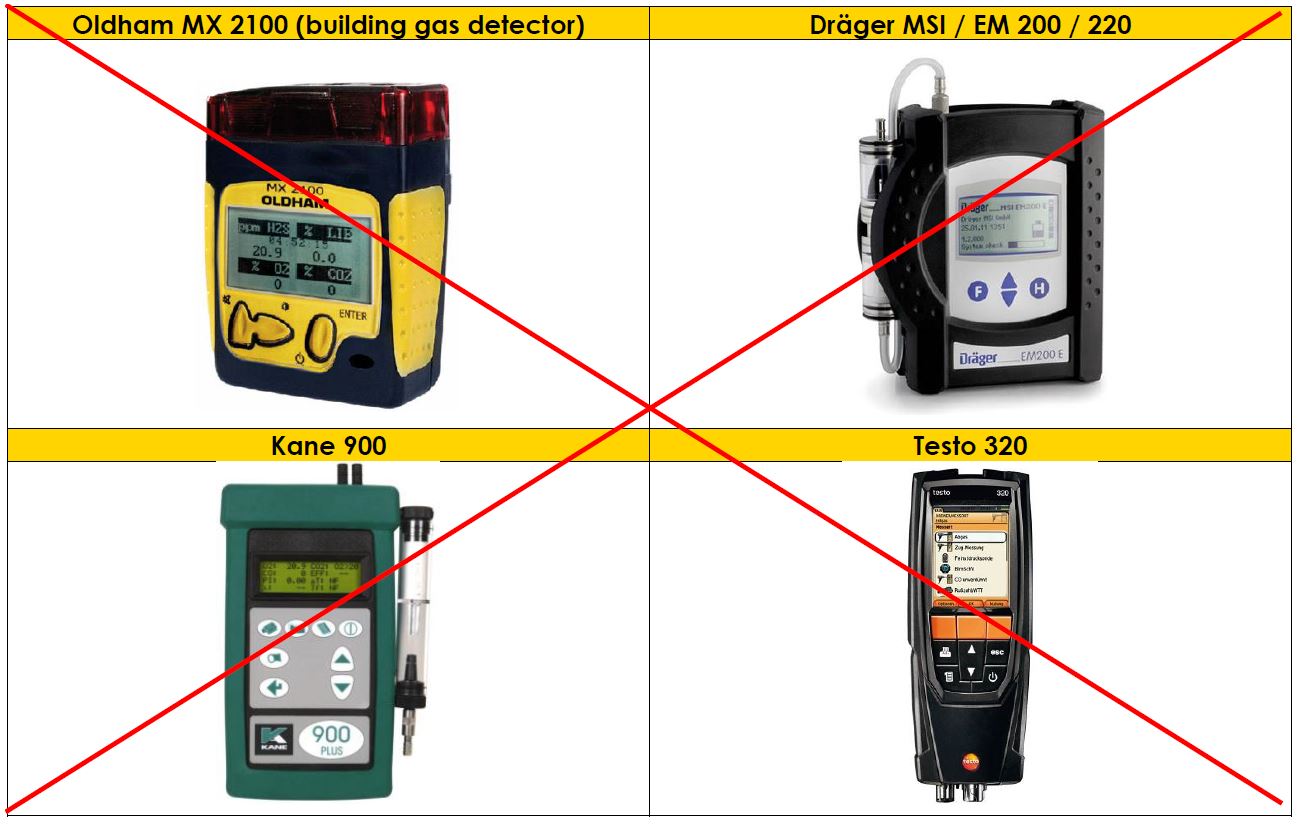

3. Check the listed activities legislation and see if the emissions are required to be normalised to an oxygen reference. If there is an oxygen reference in the legislation for this activity, it will be shown in the grey block, as highlighted in yellow beneath:

If the Listed Activities state that there is an oxygen reference, then the testing company must measure oxygen. If oxygen was not measured, reject the report. Yellow Tree has read several reports from fraudulent companies who do not measure oxygen. Without an oxygen normalisation, the results are meaningless.

4. Check whether the company that conducted the testing is a stack testing company that is a member of the Stack Testers of South Africa (STSA) under the National Laboratory Association (NLA), or whether they are an occupational hygiene company. It is often occupational hygiene companies that use incorrect gas analysers, or worse, building gas detectors, instead of compliance analysers certified to test in accordance with EPA 7e and NEMAQA.

5. Consider fining or taking legal action against Listed Activities and their testing companies who continue to use non-compliant gas analysers or building gas detectors, instead of compliance gas analysers, and who falsely report oxygen normalised results when oxygen has not been measured.

6. South African Incidents

6.1. Acid Plant in Drakenstein Municipality (subcategory 7.2: Acids)

Yellow Tree measured emissions of ± 800 mg/Nm3 of NOx. The previous fraudulent emissions testing company reported a mere ± 20 mg/Nm3 of NOx. NOx is comprised of NO and NO2, so compliance analysers must have both cells. The ± 800 mg/Nm3 that Yellow Tree measured was comprised of ± 20 mg/Nm3 of NO and ± 780 mg/Nm3 of NO2.

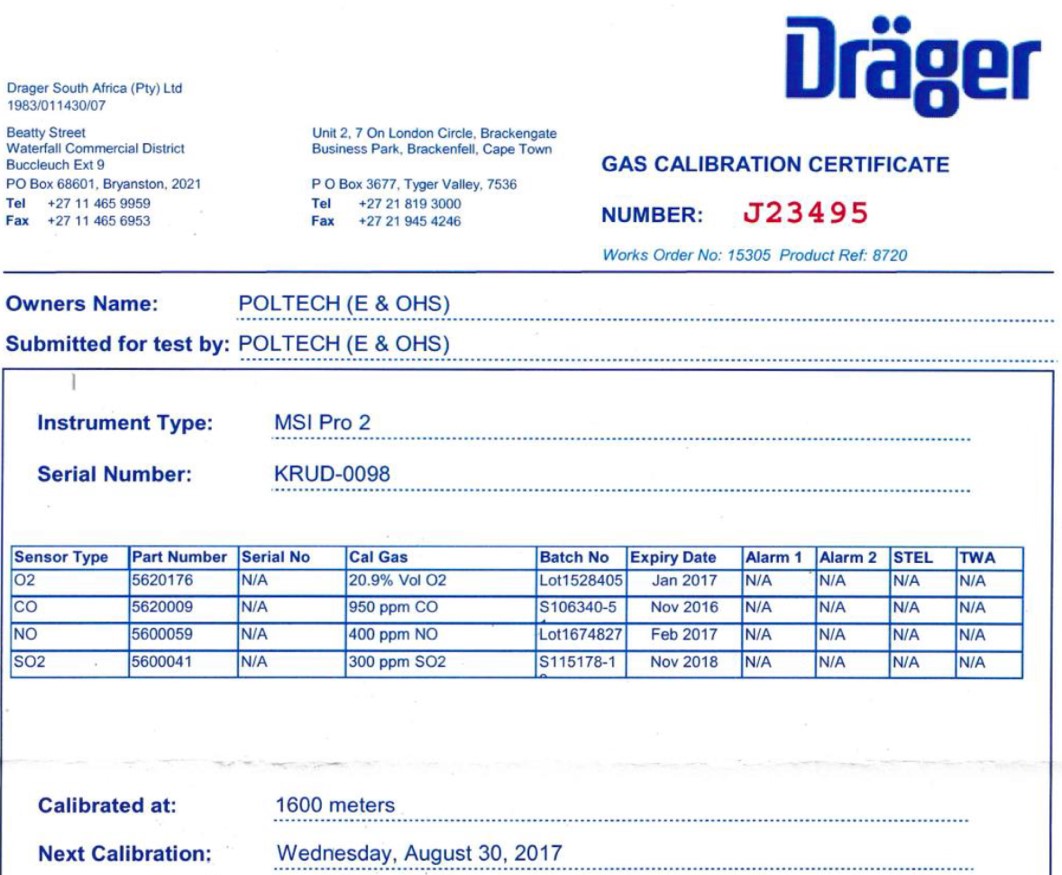

The report from the previous company, shows that a Drager MSI analyser was used. It does not have an NO2 cell. That is why only 20 mg/Nm3 was measured. The emissions have been reported as being 40x lower than they really are for years. The calibration certificate for the analyser is shown beneath.

• It does not have an NO2 cell,

• It is a Dräger MSI analyser which does not have a Peltier cooler,

• The fact that an annual calibration certificate is included in the report may indicate that this analyser is not placed on calibration gas at the start and end of every day of testing.

6.2. Coal Fired Boiler in Pinetown, Durban

Emissions of SO2 from coal fired package boilers are in the range of 600 – 1200 mg/Nm3. A mass balance reveals that these emissions correspond with the fact that South African A/B grade coal contains 0.5 – 1.0 % of sulphur. Yellow Tree measured 1 203 mg/Nm3 of SO2 using a Horiba analyser on a coal fired boiler in Pinetown, Durban. Several years later an emissions testing company allegedly reported SO2 emissions of zero on this same boiler.

This is impossible when firing coal. How did a testing company measure zero? Perhaps they did not use a gas analyser, but used a sorbent tube, gas bag or a non-compliant method. Perhaps they used an analyser and obtained incorrect readings. Gas analysers are fickle devices. EPA Method 7e acknowledges this and says that the testing company must put the gas analyser on calibration gas before and after each day of testing. Legitimate stack testing companies have calibration gas stored in their vehicles for this purpose.

Most of the fraudulent companies only put their analysers on gas once per year. If an annual calibration certificate is attached to the report, it may indicate that the analyser was not placed on gas before and after testing on the day.

6.3. Coal Fired Boiler in Musina (Section 23); Wood Combustion in Gert Sibande (Subcategory 9.5)

We have two stack testing reports written by a fraudulent testing company based in Valhalla, Centurion. This is the most fraudulent testing company that we have come across. This company does not use a gas analyser. They use a gas detector (like that found in buildings near the fire alarm) to try and measure the stack gases. The device that they use is called an Oldham MX2100.

These detectors are only capable of measuring up to 80 mg/Nm3 of SO2. But the SO2 emissions from coal fired boilers are in the range of 600 – 1200 mg/Nm3. This testing company drastically under reports the emissions of many controlled emitters and listed activities every year, misleading Air Quality Officers into believing that the public and factory workers are safe.

7. Advice

We are here to help, and our advice is always free of charge. Please email us or phone us at any time. PM2.5 was reported as leading to 3 100 000 million deaths in 2010 (World Health Organisation). It is critical that we all play a part in addressing fraudulent testing in South Africa, for the sake of the health and the future of the communities that we serve.