Stack Emissions Sampling

WHO NEEDS STACK SAMPLING?

In 2010 the very first list of activities was gazetted. It was passed under the National Environmental Management: Air Quality Act (NEMAQA) of 2004, and it was called “List of Activities which Result in Atmospheric Emissions which have or may have a Significant Detrimental Effect on the Environment.” This list of activities imposed limits on the concentration of pollutants that may be emitted from each industry. The list has been updated several times since, and today it regulates the following 69 industries within these 10 categories.

Please click the “+” sign next to your industry to see the subcategories.

Category 1: Combustion Installations

1.1 Solid Fuel Combustion Installations

1.2 Liquid Fuel Combustion Installations

1.3 Solid Fuel Biomass Combustion Installations

1.4 Gas Combustion Installations

1.5 Reciprocating Engines

1.6 Waste Cofeeding

Category 2: Petroleum Industry

2.1 Combustion Installations

2.2 Catalytic Cracking Units

2.3 Sulphur Recovery Units

2.4 Storage and Handling of Petroleum Products

2.5 Industrial Fuel Oil Recyclers

Category 3: Carbonization and Coal Gasification

3.1 Combustion Installations

3.2 Coke Production

3.3 Tar Processes

3.4 Char, Charcoal and Carbon Black Production

3.5 Electrode Paste Production

3.6 Synthetic Gas Production and Cleanup

Category 4: Metallurgical Industry

4.1 Drying and Calcining

4.2 Combustion Installations

4.3 Primary Aluminium Production

4.4 Secondary Aluminium Production

4.5 Sinter Plants

4.6 Basic Oxygen Furnaces

4.7 Electric Arc Furnaces (Primary and Secondary)

4.8 Blast Furnaces

4.9 Ferroalloy Production

4.10 Foundries

4.11 Agglomeration Operations

4.12 Prereduction and Direct Reduction

4.13 Lead Smelting

4.14 Production and Processing of Zinc, Nickel and Cadmium

4.15 Processing of Arsenic, Antimony, Beryllium, Chromium and Silicon

4.16 Smelting and Converting of Sulphide Ores

4.17 Precious and Base Metal Production and Refining

4.18 Vanadium Ore Processing

4.19 Production and or Casting of Bronze, Brass and Copper

4.20 Slag Processes

4.21 Metal Recovery

4.22 Hot Dip Galvanizing

4.23 Metal Spray

Category 5: Mineral Processing, Storage, Handling

5.1 Storage and Handling of Ore and Coal

5.2 Drying

5.3 Clamp Kilns for Brick Production

5.4 Cement Production (using conventional fuels and raw materials)

5.5 Cement Production (using alternative fuels and/or resources)

5.6 Lime Production

5.7 Lime Production (using alternative fuels and/or resources)

5.8 Glass and Mineral Wool Production

5.9 Ceramic Production

5.10 Macadam Preparation

5.11 Alkali Processes

Category 6: Organic Chemicals Industry

Category 7: Inorganic Chemicals Industry

7.2 Production of Acids

7.3 Production of Chemical Fertilizer

7.4 Production, Use in Production or Recovery of Antimony, Arsenic, Beryllium, Cadmium, Chromium, Cobalt, Lead, Mercury, and or Selenium, by the Application of Heat

7.5 Production of Calcium Carbide

7.6 Production or Use of Phosphorus and Phosphate Salts not mentioned elsewhere

7.7 Production of Caustic Soda

Category 8: Thermal Treatment of Waste

8.1 Thermal Treatment, General & Hazardous Waste

8.2 Crematoria and Veterinary Waste Incineration

8.3 Burning Grounds

8.4 Drum Recycling Processes

Category 9: Pulp and Paper Manufacturing

9.1 Lime Recovery Kiln

9.2 Chemical Recovery Furnaces

9.3 Chemical Recovery Copeland Reactors

9.4 Chlorine Dioxide Plants

9.5 Wood Burning, Drying and the Production of Manufactured Wood Products

Category 10: Animal Matter Processing

What Pollutants do we Measure??

The listed activities legislation stipulates pollutants that must be measured for each of the industries above. Yellow Tree is one of the few companies in South Africa that can measure all of the pollutants in the following table:

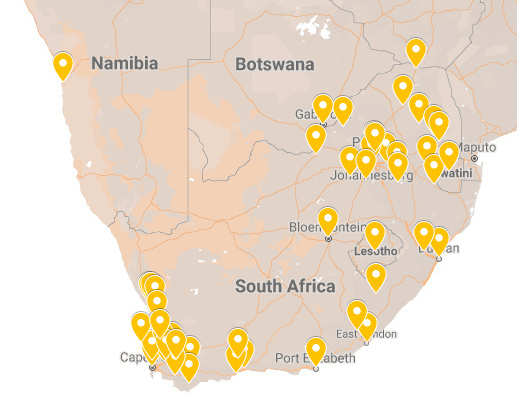

where do we operate?

Yellow Tree has offices in Cape Town, Jo’burg, and Durban and serves clients across the country and into Africa. The map beneath reveals that we are able to serve you anywhere in Southern Africa.

Why use Yellow Tree?

Is Yellow Tree the cheapest stack sampling company? No. But we represent great value. We operate with a slender single-digit profit margin, meaning that what you spend with us is spent where it matters: on the most accurate isokinetic machines and gas analysers; and on highly skilled Chemical Engineers who perform the measurements, calculations and reviews.

In addition, we avail ourselves to meet with you afterwards to answer questions and guide you towards compliance. All of this makes us more expensive than occupational hygiene companies that offer stack sampling as an add-on service. But one does not want to be penny-wise and pound foolish! The cost of non-compliance is far greater than the cost of accurate stack sampling and peace of mind that is offered by Yellow Tree.

Click here to learn more about why we feel you would benefit from Yellow Tree serving as your stack sampling partner.