Air Dispersion Modelling

What is Air Dispersion Modelling?

Air Dispersion Modelling predicts the behaviour and dispersion of pollutants in the atmosphere.

How do Air Dispersion Models work?

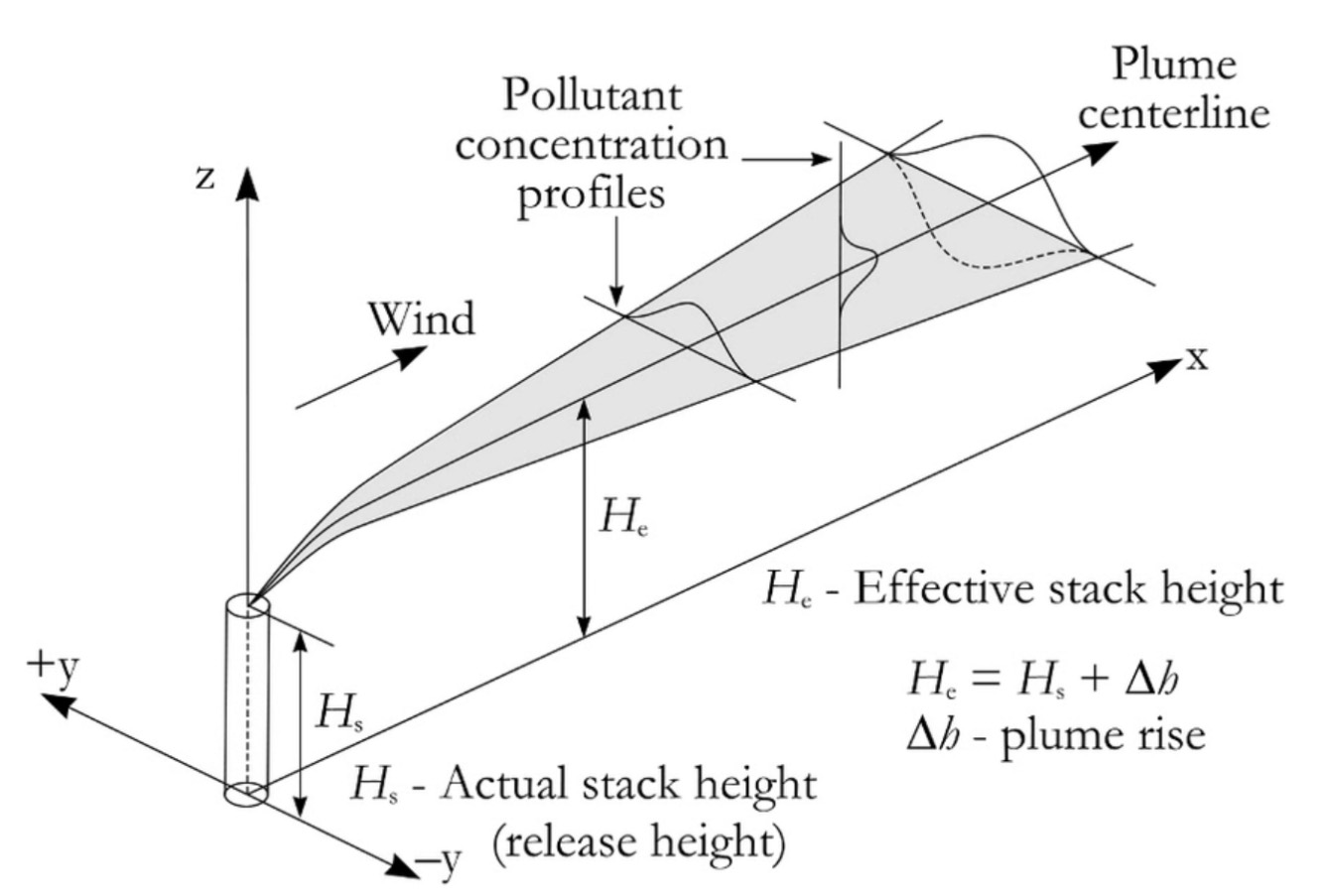

Air Dispersion Models use pollutant emission rates, emission source characteristics (e.g. the diameters and heights of chimney stacks), meteorological conditions (e.g. wind speeds and directions) and the profile of the terrain, to simulate air pollution. Modelling is done using mathematical algorithms on computers with high processing power.

What types of Air Dispersion Models are there?

Air Dispersion Models range from simple (level 1) screening models like SCREEN3 to more advanced models like AERMOD (level 2) and CALPUFF (level 3). Advanced level 2 and 3 models are more accurate than simple level 1 models. When selecting a model, it is important to consider the accuracy required for the study. One may start with a worst-case-scenario (screening) study, to determine whether a more advanced study is required. More advanced studies are more costly. When choosing a model, it is also important to consider the distance between sources of pollution and sensitive areas such as schools or hospitals. Finally, to choose the right model, one must consider the geophysical and meteorological complexity of the area.

What is a SCREEN3 (Level 1) Air Dispersion Model?

SCREEN3 is used for reasonably flat terrain and does not require the purchase of meteorological data. SCREEN3 instead assumes that worst-case meteorological conditions apply. This estimates worst-case air pollution. Therefore, SCREEN3 is used for preliminary screening to identify whether more advanced (level 2 or 3) modelling is required. If a SCREEN 3 model reveals that there is no air pollution problem, then no further modelling is required.

SCREEN3 is a simplified Gaussian plume dispersion model and is only an estimate of air pollution in the airshed. An airshed is an area with theoretical boundaries (e.g. mountains, or prevailing winds i.e. topography and meteorology) that limit pollution travelling into other areas. Airsheds may change with the seasons, or with the weather. An airshed is the full area that is likely to be affected by a pollution source. SCREEN3’s Gaussian distribution (known as the normal distribution) is characterized by a bell-shaped curve, as shown below:

Gaussian models assume steady-state atmospheric conditions, idealised turbulence, and continuous emissions from the source. SCREEN3 is a single-source model. This means that only one boiler stack or industrial process stack, for example, can be modelled at a time. The impact from numerous sources can be crudely estimated by summing individual SCREEN3 models. This would provide a conservative, worst-case estimate.

The code for the SCREEN3 model is available free of charge from the United States Environmental Protection Agency (US EPA). SCREENVIEW is a free interface for the SCREEN3 modelling code, that is provided by Lakes Environmental.

What is an AERMOD (Level 2) Air Dispersion Model?

AERMOD is recommended for near-field Air Dispersion studies that span less than 50 km. The AERMOD model can be applied to rural and urban areas, flat and complex terrain, surface and elevated releases, multiple sources and different types of sources. Different types of sources include point, area and volume sources. Point sources are typically combustion stacks (e.g. boiler stacks and dryer stacks) or industrial process stacks. Area sources are typically stockpiles, and volume sources are typically buildings. AERMOD considers how pollutants move through the atmosphere. However, AERMOD does not consider the chemical transformation of these pollutants (hence it is only a level 2 model and not a level 3 model).

Unlike SCREEN3 which is a simple level 1 model, AERMOD considers a wide range of meteorological data. This data includes wind speed, wind direction, and atmospheric stability. Therefore AERMOD models the dispersion of pollution more realistically than SCREEN3.

AERMOD is a steady-state Gaussian Plume Dispersion model. The code for the AERMOD model is available free of charge from the United States Environmental Protection Agency (US EPA). Lakes Environmental sells an AERMOD interface called AERMOD VIEW.

What is a CALPUFF (Level 3) Dispersion Model?

CALPUFF is used to model complex terrains such as the coast, and long ranges spanning more than 50 km. CALPUFF models air pollutants as discrete puffs or parcels of air, and is therefore the most rigorous Air Dispersion Model. Unlike simpler Gaussian Air Dispersion Models, CALPUFF accounts for the intricacies of non-steady-state conditions. The effects of terrain, complex meteorological data, and even chemical transformations are all modelled. CALPUFF is a non-Gaussian, non-steady-state atmospheric dispersion model.

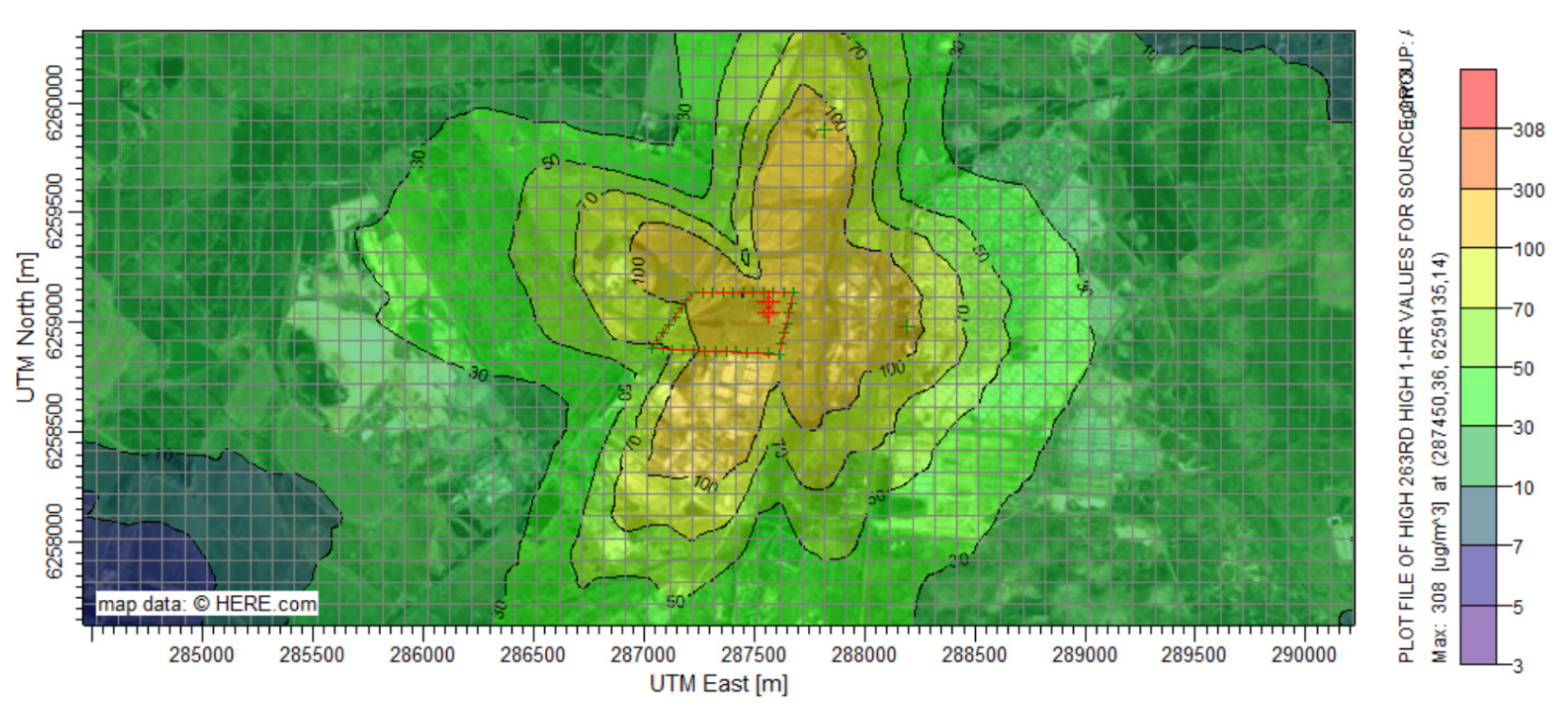

Level 2 and 3 Air Dispersion Modelling produces Isopleth Diagrams such as this one.

The code for the CALPUFF model is available free of charge from the United States Environmental Protection Agency (US EPA). Lakes Environmental sells a CALPUFF interface called CALPUFF VIEW.

Why do we use Air Dispersion Modelling?

Air Dispersion Modelling assesses the impact of new or modified sources of air pollution on local air quality. It may be used when one wants to know the concentration of pollution arising from a particular source, at another location. Air Dispersion Modelling may also be used when one wants to design a new emissions source cost-effectively while complying with ambient air quality limits. By adjusting the stack’s characteristics in the model, one can target a cost-effective design. Stack characteristics may include location, height, efflux velocity (via diameter), capping etc.

The following are real-life applications of Air Dispersion Modelling:

1. Stack Modifications at a Lead-Acid Battery Plant

High ambient lead (Pb) concentrations were measured at a lead-acid battery plant. Therefore, lead emissions from the 33 stacks were modelled. After analysing over 50 dispersion scenarios, it was determined that ambient lead concentrations could be reduced 7x by modifying the orientation of the existing stacks.

Many of the stacks at the facility featured a goose-neck design that forced pollutants downwards. This resulted in elevated ground-level lead concentrations. By straightening the stacks, the upward velocity of the exhaust gas was used to better disperse the pollutants. Air Dispersion Modelling provided a simple and cost-effective solution that significantly reduced the exposure of employees and the public to lead, which is a particularly harmful pollutant.

Furthermore, the facility will soon require Environmental Authorisation for an expansion. The competent and licensing authorities will have assurance that lead concentrations will not exceed the National Ambient Air Quality Standards (NAAQS), provided the facility makes the stack modifications. Environmental Authorisation and a varied Atmospheric Emission Licence (AEL) may then be granted.

2. High Particulate Matter (PM) in a Residential Area - Attributable to a Sugar Mill?

In a small coastal town centred around a sugar mill, there were numerous air pollution complaints from the public and many exceedances of the ambient PM limit at a local air pollution monitoring station. The sugar mill had several large boilers and was thus requested to quantify their contribution to the ambient air pollution. Being a coastal town, the licensing authority requested that a highly accurate CALPUFF (level 3) model be used. Time series concentration plots were instrumental in assessing whether measurements at the local monitoring station corresponded to the emissions from the sugar mill’s boilers.

3. Proximity of a Coal Handling Terminal to an Ammonium Nitrate Plant

The location of a proposed coal offloading terminal has been questioned as it is to be situated near an ammonium nitrate (NH4NO3) plant. If a mixture of ammonium nitrate and coal dust reach a critical concentration and is ignited by a spark, it can explode.

Air Dispersion Modelling will be used to determine whether the concentration of coal dust from the terminal will create a risk at the ammonium nitrate plant. The model will evaluate whether coal dust reduction mitigations are required and whether these mitigations will be sufficient. Should mitigation measures be insufficient, Air Dispersion Modelling could be used to determine a better location for the coal offloading terminal.

4. Sugar Mill Boiler Stack Height to Ensure Compliance with Ambient PM Limit

A sugar mill is replacing a boiler stack and wants to know how high the boiler stack needs to be to comply with the NAAQS for PM. Air Dispersion Modelling will be performed to determine ground-level pollutant concentrations resulting from the boiler’s emissions. Various stack heights and diameters will be modelled to determine the ideal stack height and efflux velocity respectively. The ideal stack height and diameter will balance ground-level air quality against stack cost.

These anecdotes illustrate the importance of Air Dispersion Modelling for industry as a design engineering tool, and for authorities in authorisation and permitting. Please contact us to see if Air Dispersion Modelling may assist the air quality compliance and cost-effective design of your project. Though we are a South African company (here is the South African Air Dispersion Modelling Legislation), our chemical engineering qualifications enable us to perform modelling globally. Please contact us – we would love to chat.